Cooperation lets you see better

Employees at the Analytics unit at Technology & Infrastructure are working directly at Creavis and Process Technology. This cooperation has made analyses faster and of higher quality.

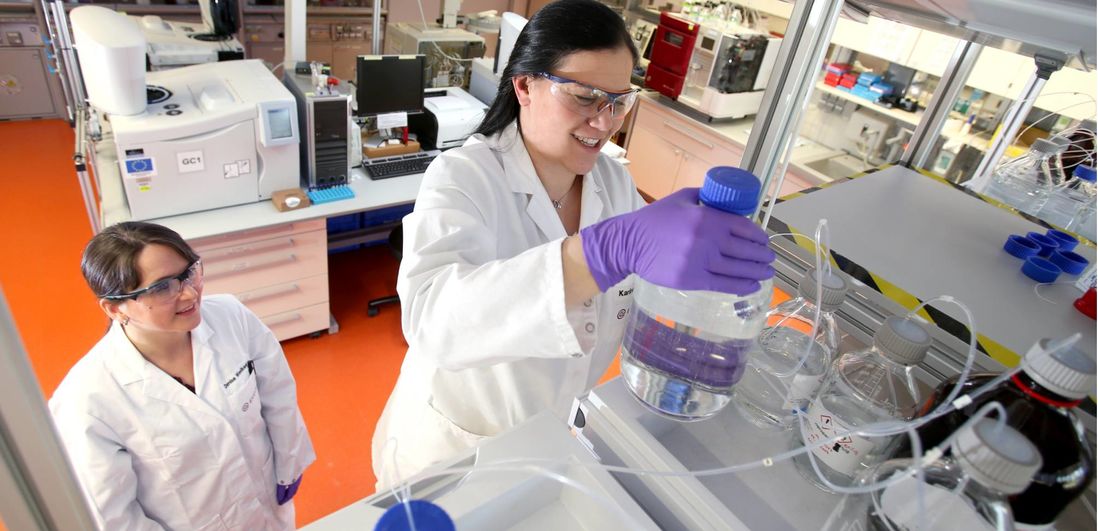

Marina Bergmann, a chemistry lab assistant at Creavis in the Marl Chemical Park, is using a pipette to extract samples from a glass shake flask. The flask contains microbes that were grown in a nutrient solution. Right next to Bergmann are the bioengineer Denise Westkamp and the chemistry lab assistant Karina Keßlau, who are filling the necessary eluents into the liquid chromatograph in order to prepare it for an analysis. The two analytics experts from Technology & Infrastructure (TI) want to determine whether the samples contain the desired products or whether any unwanted byproducts were created and how much. The paths are short here in the biotechnology lab at Creavis. This is a big advantage for everyone involved.

The core business of biotechnology research is the development of customized biocatalysts that produce large amounts of chemicals. However, the right conditions have to be created for this as well. Only a precise analysis can determine whether the microbes are doing their job properly. “We used to do the analyses ourselves,” says Steffen Schaffer, who is responsible for biocatalyst development at Creavis. “But we are experts for biotechnology, not for analytics.” Although the analyses basically worked in the past, the methods used were often insufficiently validated. Moreover, they were perhaps not ideally selected for the analytical issue in question. As an alternative, the biotechnologists sometimes took their samples to the analytics experts in the chemical park, whose workplace is several hundred meters from Creavis. Although the team there had the required analytics expertise, they had no connection to biotechnology, which is a very specialized field of research. As a result, the participants decided to have the analytics employees work directly in the Creavis laboratory. “In their own field, the analytics specialists have a completely different level of expertise than we do,” states Schaffer. The idea has paid off. Today, analyses always use the same procedure and the results are reliable and quickly available. Moreover, the staff can now directly communicate with one another because everyone works in the same rooms.

Chemistry lab assistant Marina Bergmann from Creavis is using a pipette to extract samples

Miriam Schwarzer bestückt den Gaschromatografen bei der Verfahrenstechnik mit Proben.

Probenfläschchen für die Analyse

Schwarzer repariert einen in die Anlage integrierten Chromatografen. Stefanie Dehmer (rechts), Mitarbeiterin im Technikum der VT, analysiert regelmäßig selbst Proben aus der Anlage.

REAL DETECTIVE WORK

“We also know alternative methods,” says Miriam Schwarzer, Head of Analytical On-site Service at TI, about another advantage of the cooperation. This is especially important “when we see a compound that we aren’t familiar with,” adds Schaffer. Real detective work is needed in such cases: Is it an organic compound? How many carbon atoms does it contain? Does it have a biological source? The compound’s structure is revealed with the help of mass spectrometry and chromatography. “We can also use the findings for other projects,” explains Schwarzer. Appropriate databases have already been created for this purpose.

POOLED EXPERTISE

The departments for Reaction and Polymer Technology as well as the Fluid Processing unit at Process Technology (VT) have now also decided to directly collaborate with the analytics experts. A team of process engineers and analytics specialists are taking care of the methods, equipment, software, and training programs for all of the departments. In addition, they are responsible for the analytics testing lab. The experts from the various facilities can also be on board if they want to be. The Technology Center’s employees conduct most of the analyses and evaluations themselves. The team provides assistance whenever questions or problems arise. “The colleagues from Analytics contribute special knowledge that we don’t have in this form at Process Technology,” says Achim Lienke, Head of the Reaction Research Technology Center in Marl. Examples include their skill with equipment maintenance and the development of new methods. Whenever a measurement fails to supply suitable results, Miriam Schwarzer from Analytical On-site Service has no qualms about using tools herself in order to tighten screws, remove dirt, and check to see if instruments are damaged.

CRITICAL MASS

Process Technology contributes its experiences in other areas, including the online connection of analytic devices such as gas chromatographs, which are installed directly in the facilities. Other contributions include its knowledge of special analytical methods and of equipment and analysis software. “Together, we have the critical mass we need to push ahead with a lot of things. Other units can benefit from this as well,” says Lienke. This approach not only improves quality, it also ensures that the harmonization of methods makes progress. “We want to use fewer analytical methods in the future so that we can always get comparable results and thus also save time,” says Lienke, who sums up his experiences of the cooperation as follows: “The analytics experts act as our eyes. For us, it’s crucial that we can take a close look.”